| Line 336: | Line 336: | ||

<tr> | <tr> | ||

<td> | <td> | ||

| − | <b>November , 2011 ( hours):</b> | + | <b>November 3, 2011 (7 hours):</b> |

<br> | <br> | ||

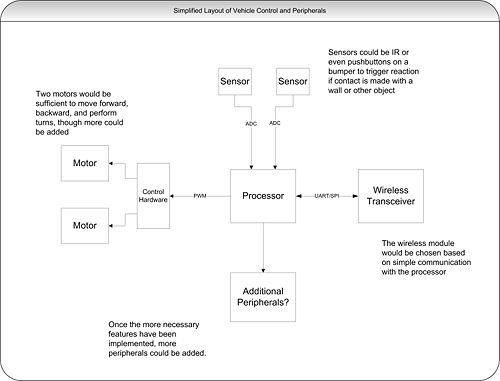

| − | + | Looked at an example PWM program for the micro and looked up information in the datasheet. PWM mode can be chosen for each channel in each of the four timers. This is selected by setting the TIMx_CCMRx register correctly.In PWM mode (1 or 2), TIMx_CNT and TIMx_CCRx are always compared to determine whether TIMx_CCRx≤ TIMx_CNT or TIMx_CNT≤ TIMx_CCRx (depending on the direction | |

| + | of the counter). The duty cycle can be adjusted with the TIMx_CCRx registers. I tried to combine the PWM initialization code with ADC initialization code and LCD code to control the CCR register with the ADC value, but have not gotten it to work yet. Thus the code used manually controlled the the PWM at a specific frequency and duty cycle.<br><br> | ||

| + | I tried our circuit again for PWM motor speed control, and after an hour or two when the rest of the group came we figured out that the 2N3704 NPN BJT we were using was being fried by the collector to emitter voltage/current. We found this out when we noticed one became burning hot and did not operate correctly. Scott and I went to radio shack and got two TIP 120s. We rebuilt the circuit.--more to come | ||

</td> | </td> | ||

</tr> | </tr> | ||

| Line 349: | Line 351: | ||

<u>Accomplishments</u>: | <u>Accomplishments</u>: | ||

<br> | <br> | ||

| − | <u>Weekly Work Total</u>: | + | <u>Weekly Work Total</u>: hours |

<br> | <br> | ||

| − | <u>Project Work Total</u>: | + | <u>Project Work Total</u>: hours |

</td> | </td> | ||

</tr> | </tr> | ||

Revision as of 18:47, 3 November 2011

Contents

Jason Holmes - Design Notebook

Week of Sept. 19 |

|

September 21, 2011 (1.5 hours):

|

|

September 22, 2011 (20 minutes):

|

|

September 23, 2011 (1 hour):

|

| WEEK SUMMARY: Accomplishments: Obtained usernames for HKUST members

|

Week of Sept. 26 |

|

September 27, 2011 (45 minutes):

|

|

September 27, 2011 (30 minutes):

|

|

September 28, 2011 (1 hour):

|

|

September 29, 2011 (45 minutes):

|

|

September 30, 2011 (1.5 hour):

|

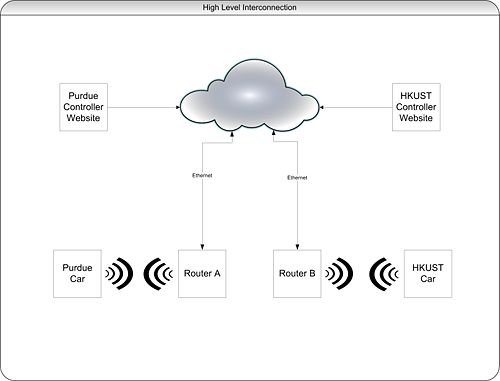

| WEEK SUMMARY: Accomplishments: Completed preliminary block diagram layout of system. Decided on potential processor family.

|

Week of Oct. 3 |

|

October 6, 2011 (2 hours):

|

|

October 7, 2011 (1 hour):

|

|

October 7, 2011 (1.5 hours):

|

| WEEK SUMMARY: Accomplishments: Finished poster for VIP poster session

|

Week of Oct. 10 |

|

October 11, 2011 (30 minutes):

|

|

October 13, 2011 (1 hour):

|

|

October 14, 2011 (1.5 hours):

|

| WEEK SUMMARY: Accomplishments: Decided on a development board to begin prototyping.

|

Week of Oct. 17 |

|

October 17, 2011 (30 minutes):

|

|

October 17, 2011 (1 hour):

|

|

October 18, 2011 (3 hours):

IP Camera:TRENDnet TV-IP110WN Wireless N Internet Camera

|

|

October 19, 2011 (2 hours):

|

|

October 20, 2011 (1 hour):

|

| WEEK SUMMARY: Accomplishments:

|

Week of Oct. 24 |

|

October 25, 2011 (3.2 hours):

(640 x 480 pixels) X (2 bytes per pixel) = 614,400 bytes per frame All of the CMOS cameras output in a RGB format or similar - raw image data. For most cameras, this is 16 bits per pixel. Without doing our own compression, this image data would be impossible to send wirelessly. There is a library for C to convert RGB data to JPEG format, which then possibly be converted to MJPEG on the controller side. This could possibly be used on-board, but the speed would have to be tested.

|

|

October 28, 2011 (1.5 hours):

|

| WEEK SUMMARY: Accomplishments:

|

Week of Oct. 31 |

|

November 1, 2011 (4.5 hours):

|

|

November 3, 2011 (7 hours):

|

| WEEK SUMMARY: Accomplishments:

|